Building a Beautiful City

Creating an Ideal Life

Location: Shanghai

Project period: 2021-2022

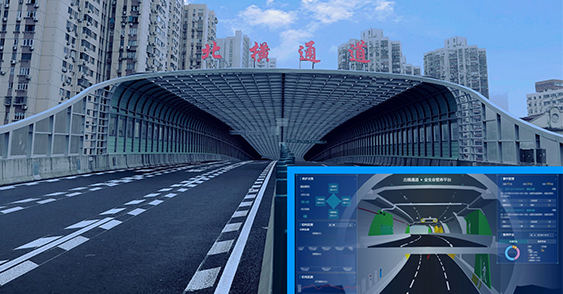

Introduction: It is a three-dimensional integrated management and control solution of "view, management, and prevention" for the government's road and transportation administration departments, using a new generation of digital twin technology to empower digital innovative applications of facilities and ensure the safety of bridge operation. The system can realize real-time "cloud" management, including universe awareness, intelligent alarm, and cross-department collaboration to improve disposal efficiency, visual control to improve the quality of information communication, optimized deployment of predictive emergency resources to shorten the time of emergency response, and management and maintenance of facilities throughout the life cycle based on state awareness to improve the service quality of facilities. Launched in February 2022, the system was immediately followed and reported by CCTV News and other media. In June 2022, Shanghai Media Group made a documentary about the system on DRAGON TV as an excellent case of improving the modernization of urban governance. In the future, "Cloud Road Center" will continue to upgrade and evolve. On the basis of 1.0, it will actively expand the application scenarios of digital passenger transport supervision and resident travel services, and gradually form a "smart brain" covering the four core areas of road facilities management, transportation service management, dynamic safety supervision and static traffic supervision, so as to enhance the modernization of road transport governance.

Location: Shanghai

Project period: 2020-2021

The platform is a comprehensive urban grid management system integrating road network facility management, emergency resource management, maintenance plan management, operation monitoring management and emergency management, so as to control the operation status of road network facilities in megacities in real time and comprehensively, and greatly improve the operation and maintenance service level of urban transportation infrastructure. The platform has digitized the documentation of 1,900 km of road, bridge and tunnel infrastructure, deployed the fine management of 10-meter-level road network, managed 5000+ users, 2000+ suppliers, 2000+ professional vehicles and 200+ maintenance bases with mature big data management and decision-making mechanism, processed 5TB of data annually, received 200,000 work orders and handled 100,000 incidents. The data accumulation and management mode has been continuously iterated and optimized. The overall control of urban operation safety, operation efficiency and facility safety state has been improved, the human cost expenditure has been greatly reduced, the management resources and cost input have been optimized, and the digital transformation and high-quality development of urban operation management have been supported.

Business Section:Architecture

Location:Luanda, Angola

Project Completion Date:12, 2009

Construction Mode:EPC

Project Category:Stadium Construction

Luanda Angola Stadium, the main stadium of African Nations Cup in 2010 is the largest symbolic architecture in Angola, which occupies 90,000 square meters and is capable of accommodating 50,000 people to watch the game. Since STEC entered Angola market in 2005, we have conducted a series of projects through many years of efforts. In 2008, as the general design construction contractor, STEC took over the work of building Luanda Angola Stadium, the largest single architecture in Angola. The project employs large-span architectural design and the main structure is three-dimensional steel construction extending around, looking like antelope horns on African prairie as a whole. During construction, by means of resource advantage and technical strength in Angola, STEC smoothly solved problems such as complicated structure, tight schedule, high-technical requirement and the shortage of local building materials, in particular lack of water and power supply conditions, thus it received continuous compliments from local governments at all levels and won "The Best Contractor” prize issued by the local government. STEC is the first international general contractor to be received personally by the president in person in Angola history.

Business Section:Tram

Location:Huai’an, Jiangsu Province

Project Starting Date: 03, 2014

Participating Mode:BOT

Power Supply System:Energy Storage

Project’s Breakthrough:First Tram crossing City Center in China

The project is signed between STEC and Jiangsu Huai’an government, in the Build-Operate-Transfer mode including investment, design, construction, operation and equity transfer. The total investment of Huai’an tram project is 3.445 billion yuan and the economic indicator is 172 million yuan/km for the main line. Among which a total investment of the tram project is 3.033 billion yuan and its economic indicator is 151 million yuan/km for the main line. The “BOT + Equity Transfer” investment and financing model we use allows the local government to have more flexibility in carrying out the project and balance the budget and cost. The tram, as a ‘new industry’, is also the best alternative for Huai’an government who cannot afford the huge investment in constructing metros. The first phase of Huai’an modern tram is 20.3 kilometers long, all 23 stations are above the ground, and has 4 large underground tunnels, and a depot. Huai’an tram uses a catenary-free power supply which is also the longest catenary-free power supply tramway in China. The tram uses the super capacitor which enables the vehicle to be fully charged in only 30 seconds in the station and a long life cycle of 10 years. In braking, the vehicle’s kinetic energy can be recycled into electrical energy. Huai’an modern tram connects Qinghe District, Huai’an development zone, ecological town, Huai’an District and the city’s commercial center, business center, administrative center, and culture and tourism center, becoming the first tram crossing the city center in China. It provides a reference in tramway construction for other cities, and also motivates the national transport industry towards green and energy-saving development.

Business Section:Tunnel

Location:Shanghai

Project Completion Date:Dec. 2014

Participating Mode:EPC

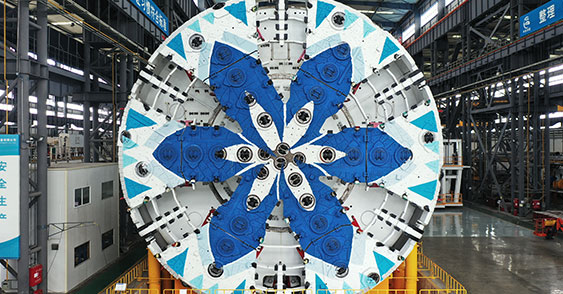

Shield Parameter:15m- Diameter Articulated Slurry Balance Shield

Project’s Breakthrough:Massive-Diameter Shield Tunnel Continuously Crossing Six Metro Tunnels in Operation and 92 Buildings

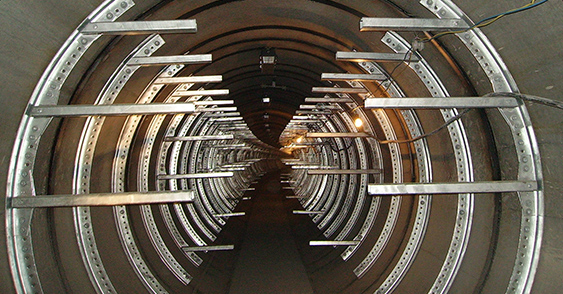

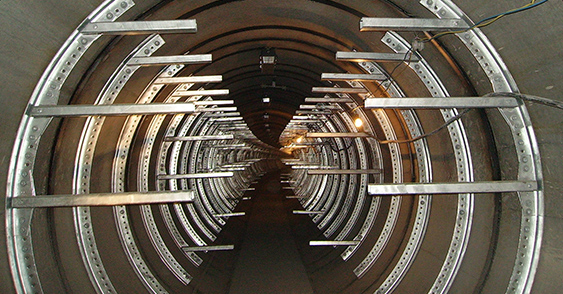

The North Cross Channel is a "horizontal" road of Shanghai’s "three vertical and three horizontal" skeleton network. In the early 1990s, constructing highway for the whole line was the plan. However, the huge size of the highway would tear apart the precious city ground space permanently, occupy public space and impact the surrounding community while the underground tunnel scheme had been stalled for years due to too many construction difficulties. In 2014, thanks to the continuous technological innovation in the field of construction, STEC succeeded in making the North Cross Channel an underground one. After commanding the use of large diameter shield and overcoming the building settlement challenge in Yangtze River and the Bund Tunnel, STEC now has the ability to ensure the safety and quality of the tunnel construction with the highest degree of difficulty and risk in the world. During the construction, STEC will push 15.59 meters’ diameter super large shield excavating from downtown Weining Road, continuously crossing the six metro tunnels in operation and 92 buildings in 6.4 kilometers, turning directions with minimum 500 meters’ radius, overcoming the tunnel lining structure, seal, construction risk and many other challenges. STEC conquered the challenging underground traffic queue in spite of heavy underground traffics and buildings.

Business Section:Tunnel

Location:Shanghai

Project Operation Date:10, 2009

Participating Mode:Managing Contractor

Shield Parameter:15.43m Slurry Balance Shield

Project’s Breakthrough:World’s Longest Distance shield tunnel with Single Excavation and largest diameter When Completed

Shanghai Yangtze River Tunnel epitomizes the highest technical standard of shield method tunnel construction in the world. The overall length of the tunnel is 8.95 kilometers. We used a slurry balance shield, which is 15.43 meters in diameter, developed and manufactured by STEC and German Herrenknecht AG together, to excavate 7.45 kilometers in the tunnel, 55 meters deep at the bottom of the Yangtze River. This project broke three world records at that time, the largest shield diameter, the longest distance with single excavation, and the deepest buried depth. During the construction of Yangtze River Tunnel, the three major challenges STEC faced were “length, width and depth”. In accordance to the design, construction and disaster prevention of oversize-diameter and extra-long distance shield tunnel under the condition of complicated soft soil stratum, STEC mastered the stability of oversize-diameter shield tunneling and the accuracy of extra-long distance shield tunneling, resolving seven world-class technical difficulties including the synchronous construction technology which prevents the tunnel from floating, overcoming 50 crucial construction problems and furthermore, creating the global standard of extra-large tunnel construction in future cities. Yangtze River Tunnel is also the first shield tunnel adopting all-around stagger assembling craft in our country. STEC manufactured 74,710 pieces of large reinforced concrete segment for its production, and the precise fault margin of which is lowered under 0.5 millimeter, which ensured the quality of the tunnel form.

At present, the Shanghai Yangtze River tunnel has won various domestic tunnel construction awards, including China Civil Engineering Jeme Tien Yow Award, Gold Medal of National Quality projects and others. It also became the first Chinese tunnel project to win "The Tunnel Award" from International Tunneling Association.

Business sector: Tunnel / rail transit / underground space

Location: Hangzhou City, Zhejiang Province

Commencement time: January, 2020

Participation mode: EPC design, construction and investment

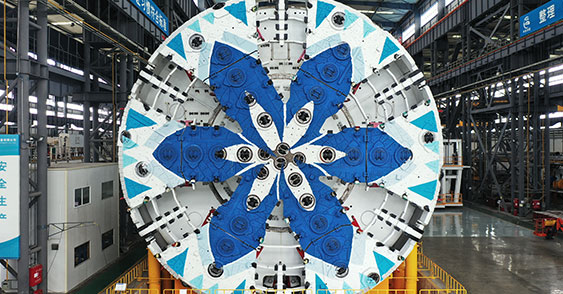

Shield tunneling machine specifications: Slurry balance shield tunneling machine with a diameter of 15.76m

Project breakthroughs: The first shield tunnel for both highway and railway purposes in Zhejiang Province, and the largest shield tunnel in Eastern China.

Project introduction: Qinwang Tunnel is the first shield tunnel for both highway and railway purposes in Zhejiang Province. The tunnel section, with a total length of 2,868 m, crosses the Fuchun River and connects the Qinwang Square, the "City Eye" of Qinwang, and the Zhongsha district. It works as a crucial infrastructure that improves the cross-rive traffic system in Fuyang. The shield section of left line contracted by STEC is as long as 1,254 m. The outer diameter of tunnel segment is as long as 15.2 m and the inner diameter is 13.9 m. simultaneously, STEC also constructs the underground complex of Qinwang Square, the Qinwang Square Station of rail transit and the relevant ancillary works. The project, upon its completion, will open up the North-South traffic artery of Fuchun Bay in Fuyang, Hangzhou, connect the golden axis of Fuyang rail transit, and thus accelerate the high-quality development in urban integration.

Business sector: Water conservancy and water utilities

Location: Shanghai

Commencement time: January, 2018

Participation mode: Engineering procurement construction

Shield tunneling machine specifications: Slurry balance shield tunneling machine with a diameter of 11.73m

Project breakthroughs: Super-deep diaphragm (103 m) and ultra-deep foundation pit (56.6 m)

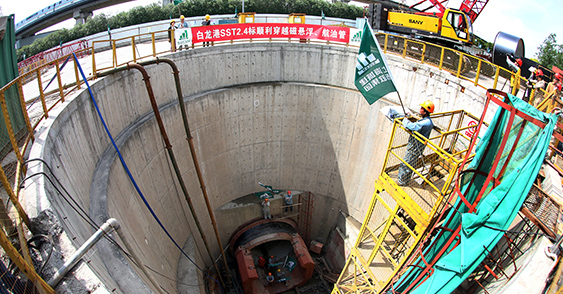

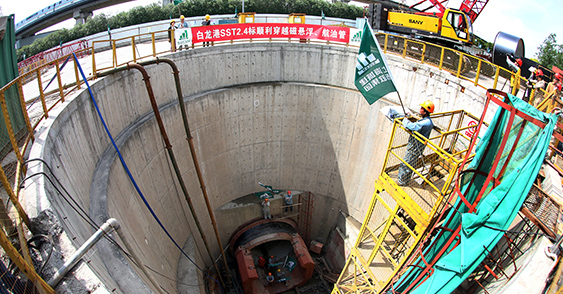

With a total length of 15.3 km and a water retention capacity of over 700,000 cubic meters, the deep drainage and storage pipeline system engineering of Suzhou River serves as a key link for Shanghai to systematically develop its in-deep underground space for the first time and to construct "sponge city". The capacity of drainage system along the Suzhou River can be promoted from once every year to once every five years after the whole project is completed. In this way, Shanghai can effectively address the once-in-a-century rainfall and basically eliminate the initial rainwater contamination along the Suzhou River. The Miaopu experimental section undertaken by STEC is as long as 1.61 km. The buried depth of the tunnel will be from 42 m to 60 m. In this experimental section, STEC constructed a round shaft foundation pit as deep as 56.6 m, the deepest foundation pit in soft soil in China. Ultra-deep shaft construction technology is becoming the benchmark for similar projects in the future. It will provide referential significance for the future development and utilization of underground space.

Business sector: Rail transit - urban railway

Location: Shanghai Municipality

Commencement time: June, 2019

Participation mode: Engineering procurement construction

Shield tunneling machine specifications: Slurry balance shield tunneling machine with a diameter of 14.05 m and earth pressure balance shielding machine with a diameter of 9.295 m.

Project breakthroughs: STEC adopted the 107.5-m super-deep diaphragm to dig a foundation pit as deep as 44 m, of which both are the greatest in the Shanghai rail transit field.

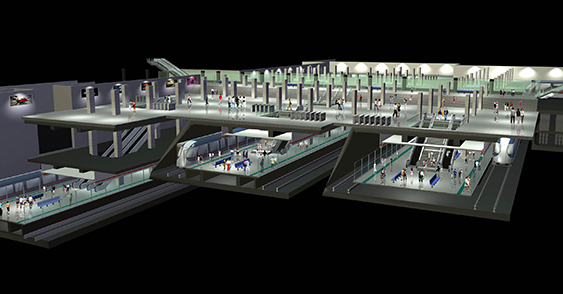

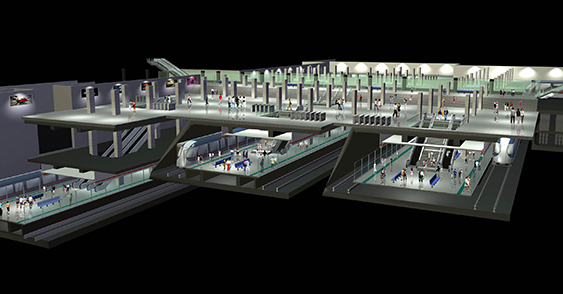

The airport connection line project in urban rail transit line of Shanghai Metro has a total length of 68.6 km and passes through Minhang, Xuhui and Pudong Districts, with 9 stations throughout the line. The project is scheduled to be completed for operation in 2024. At that time, the transit time between Hongqiao Airport and Pudong Airport is expected to be within 40 minutes. The airport connection line project is the first rail transit project that connects the national railway in China. As an east-west fast track connecting Hongqiao hub and Pudong hub, the project contributes to enhancing Shanghai radiation and service functions to the Yangtze River Delta. It provides strong support for Shanghai to improve its urban capacity level and core competitiveness, and to implement the national strategy of integrated development in the Yangtze River Delta. STEC undertook the construction tasks at Sections 3, 4, 5 and 12 in the airport line. They involve difficulties and highlights in ultra-low altitude construction work, super-deep diaphragm construction, ultra-long precipitation, super-large foundation pit construction, ultra-high structure construction, ultra-close crossing, internal assembly construction with fully prefabricated tunnel segments, etc.

Business sector: Tunnel

Location: Nanjing City, Jiangsu Province

Commencement time: May, 2020

Completion / operation time: To be completed.

Participation mode: Engineering procurement construction

Shield tunneling machine specifications: Slurry balance shield tunneling machine with a diameter of 15.07m

Project breakthroughs: The deepest silt soil and silt foundation pit in Nanjing; the shield tunneling machine penetrates the Yangtze River levee twice.

The river-crossing tunnel under West Jianning Road, Nanjing begins at the intersection of Xingpu Road and Jiangbei Avenue in Jiangbei New District; its main line, constructed with a bridge over Jiangbei Avenue, ends near the intersection of Jianning West Road and Rehe Road. The route has a total length of about 6,801 m, of which the tunnel section is as long as about 3,550 m (Including opening section), the subgrade section is as long as about 336 m, and the elevated section is as long as about 2,915 m. “Jianning” slurry balance shield tunneling machine with a super large diameter of 15.07 m was adopted for tunnel construction. The shield tunneling machine will penetrate through the Yangtze River levee, Nanjing Metro Line 5 and other sensitive buildings in succession. The construction of river-crossing tunnel under West Jianning Road is of great significance for Nanjing to speed up the construction of Jiangbei New District, improve the capacity of Yangtze River trunk, relieve the traffic pressure of the main city across the Yangtze River, and keeps promoting the regional road network system.

Business sector: Tunnel

Location: Foshan City, Guangdong Province

Commencement time: April, 2021

Participation mode: EPC design, construction and operation

Shield tunneling machine specifications: Slurry balance shield tunneling machine with a diameter of 15.56m

Project breakthroughs: It is first shield tunnel with a super-large diameter in Guangzhou-Foshan area that penetrates through the Nanzhuang wharf in operation and the embankments on east and west banks.

Section B in the westward route extension project of Jihua Road in Foshan is about 5.404 km in its full length. The whole route was constructed under the first-class highway standards in view of urban road functions. The project forms a part of the first-ring road westward expansion strategy of Foshan. It will become a new part of the Guangzhou-Foshan one-hour traffic circle that connects the west wing of Nanhai area, Gaoming, Sanshui with downtown area of Foshan City, and help Foshan to be better integrated into the Guangdong-Hong Kong-Macao Greater Bay Area.

The controlled westward route extension project of Jihua Road in Foshan undertaken by STEC is a pair of single-layer shield tunnels with six lanes in two directions. The left line of shield tunnel is as long as 1,472 m and the right line is as long as 1,474.202 m. The section under river is as long as 920 m. The “Jihua No.1” shield tunneling machine employed is the first slurry balance shield tunneling machine with a super large diameter in Foshan and the largest one in Guangzhou-Foshan area. It marks an important milestone for the transport infrastructure construction in Foshan.

Business sector: Water conservancy and water utilities

Location: Shanghai

Commencement time: September, 2021

Participation mode: Engineering procurement construction

The Phase Ⅲ reconstruction and expansion project of Shanghai Songshen Water Environment Purification Co., Ltd. is located on the south of the company, the south side of Tongxin Road and the east side of Beimaojing. The construction contents involve the sewage plant and the pipeline for pump station outside the plant. The sewage plant involves the following tasks: Upgrade and reconstruct Phases I and II, and expand the capacity of Phase Ⅲ; the treatment capacity of Phase I and II is 140,000 m3/d; upgrade and reconstruct the current situation of Phases I and II, and reduce the capacity by 20,000 m3/d; the sewage treatment capacity will be expanded by 80,000 m3/d in Phase Ⅲ. After the reconstruction and expansion, the whole plant will receive new actual processing capacity of 60,000 m3/d, and its total processing capacity will be 200,000 m3/d. This will greatly improve the sewage treatment capacity in Songjiang area. The effluent quality will not be lower than Grade A standard. That is of great significance for the water source protection in the upper reaches of Huangpu River, the local ecological environment protection and the livelihood improvement.

Business sector: Water conservancy and water utilities

Location: Shanghai

Commencement time: December, 2020

Participation mode: Engineering procurement construction

Project breakthroughs: In this project, STEC applied the prefabrication and assembly technology on large scale and in large volume for the first time into the field of water utilities engineering. A total of 2,488 prefabricated components were adopted, with a maximum height of about 10.12 m and the heaviest weight of 31.13 tons.

Located at the plant with a processing capacity of 500,000 m3/d on the west side of Zhuyuan, Bid ZYSQ 1.3 for Phase IV project of Zhuyuan Sewage Treatment Plant mainly include the following tasks: Construct a new AAO biological reaction tank with a capacity of 500,000 m³, a horizontal sedimentation tank and other buildings / structures; adopt the five-axis mixing pile, the composite steel pipe pile through PC construction method, the UHPC ultra-high performance concrete, and other emerging technologies. In this project, STEC applied the prefabrication and assembly technology on large scale and in large volume for the first time into the field of water utilities engineering. While ensuring the project quality and controlling the project risk, STEC also accumulated important experience for the engineering application of prefabrication technology into the future water utility industry.

Since the commencement, the project department has been awarded many honors, such as Shanghai Civilized Construction Site, Shanghai Green Model Construction Site, Shanghai Five-star Construction Site, Feature Project in Practical Achievements Competition among Major Projects in Shanghai, Excellent Team, etc.

Business sector: Water conservancy and water utilities

Location: Shanghai

Commencement time: May, 2022

Participation mode: Engineering procurement construction

Shield tunneling machine specifications: φ3000 Slurry balance shield tunneling machine

Project breakthroughs: Segmental hoisting construction and slurry wall stability control for the super-deep diaphragm under complex environment.

The bid TP1.3 for initial rainwater regulation project of Taopu Sewage Treatment Plant mainly involves the rainwater collection pipeline system on the east side of Zhenjiang Village and at Zhenguang Village, which adopt the construction technologies of shield tunneling method and pipe jacking method.

All of the work shafts in this project are located at the intersections of municipal roads, and surrounded by many communities, busy commercial zones, large traffic flow and complex pipelines. In order to minimize the impact on surroundings, STEC optimized the construction technology and well structure. The project department actively connected with the local stakeholders, optimized the construction site and traffic organization, and substantially reduced the road area occupied by each shaft; the project department also canceled one pipe jacking shaft and two inspection shafts. That eases the surrounding traffic pressure and provides a reliable guarantee for orderly operation of Shanghai Municipality.

Business sector: Water conservancy and water utilities

Location: Yueyang City of Hunan Province

Commencement time: March, 2021

Participation mode: PPP project

Project breakthroughs: With a total investment of CNY 701.2 million yuan, the project, upon its completion, will provide a largest water supply plant with a capacity of 100,000 m³/d for Xiangyin people. It will supply high-quality production and living water for 300,000 people in the urban and southern areas.

The project sees a total investment of about CNY 701 million yuan. Its main construction contents include water intake engineering, water distribution network and water purification plant project. Its water source is located in the main stream of Xiangjiang River at Wanhe Village in Jinghe Township, with a construction length of 34.73 km and a water supply capacity of 100,000 m³/d.

Since the full commencement of Xiangyin Water Supply Plant project on March 6th, 2021, the project team confronted many difficulties, such as large workload, multiple units and tight construction period. They deployed the backbone, remained on the construction site, and successively overcame a series of difficult nodes, such as temporary land acquisition, river crossing, house demolition and relocation, and operation under high-voltage power lines.Upon its operation, the project will comprehensively increase the water supply quality and capacity in urban and rural areas of Xiangyin, promote the penetration rate of rural tap water, and enhance the weak link in drinking water facilities of Xiangxian County. The project will also reinforce the ability to ensure safe drinking water so that 400,000 urban and rural residents in Xiangyin can drink safe water. As a key livelihood project in the urban and rural water supply integration strategy, the project will play a crucial role in coordinating urban and rural development and accelerating rural revitalization in Xiangyin.

Business sector: Water conservancy and water utilities — Channel improvement

Location: Shanghai

Commencement time: December 23rd, 2021

Participation mode: Engineering procurement construction

The 2021 comprehensive small watershed improvement project for clean eco-system in Huinan Town involves five aspects, namely river and lake system treatment, non-point source contamination control, comprehensive prevention and control of soil and water loss, ecological restoration, and living environment improvement. It mainly covers 80 reaches of river courses in Huinan Xiaohuangpu and Laogang River, 10 groups and 1 tributary in Yuandong, 5 groups and 1 tributary in Yuandong, etc.

The project team adopted water reoxygenation technology to aerate the river course. By improving the ecological environment in the local waters, the team restored the aerobic microbial community and thus ensured the survival of plankton and fish. By virtue of the biological seine technology and the principle of biological pollution control, plants were able to absorb nutrients in the water and to form biofilms to purify water. The team adopted biological seine as a framework to control the growth area of plants so as to avoid the secondary contamination caused by floating plants growing uncontrollably in the water. They employed a plant-floating bed technique, and planted aquatic plants, such as reeds, on the water surface. Those plants are effective in suppressing phytoplankton, improving water transparency, and lowering COD. While purifying water, they can create habitats for birds, fish and other living beings, and improving the landscape.

The comprehensive small watershed improvement project for clean eco-system works as an important basic project for the local government to implement the rural revitalization strategy. It is of great significance to prevent and control soil erosion, promote ecological restoration and protection of rivers and lakes, improve overall agricultural productivity, facilitate the development in green industry, and construct the rural development pattern of harmonious co-existence between man and nature.

Business sector: Water conservancy

Location: Shanghai

Commencement time: July 2021

Participation mode: Engineering procurement construction

Channel improvement of Chuangxin River in Zhangjiabang Wedge Green Belt (Cuibai Road - Niuqiao Port) and Niuqiao Port (Majiabang - Guanglan Road) is located in Jingang Road of Pudong New Area. The improvement center covers a total length of 1,152 m, among which the length of channel to be improved in the Chuangxin River is 529.2 m. The reach starts from Cuibai Road in the north and ends at Niuqiao Port in the south. The length of channel to be improved in Niuqiao Port is 622.8 m, which starts from Majiabang and ends at Guanglan Road. In this project, STEC constructed about 2, 300-meter revetment, 3,000-meter flood control channel and 13,800-square-meter green space.

The improved Chuangxin River in Zhangjiabang Wedge Green Belt and river channel at Niuqiao Port demonstrate the unique landscape charm of ecological banks with their brilliant ecological appearance. Meanwhile, the project can revitalize the regional water systems, create a natural, comfortable and pleasant river landscape, and further improve the regional capacity for flood control, water logging removal, irrigation regulation and storage. It not only enhances the natural environment on the surrounding land but also "refresh" the life of local residents.

Business sector: Water conservancy and water utilities

Location: Shanghai

Commencement time: January 2021

Participation mode: Construction

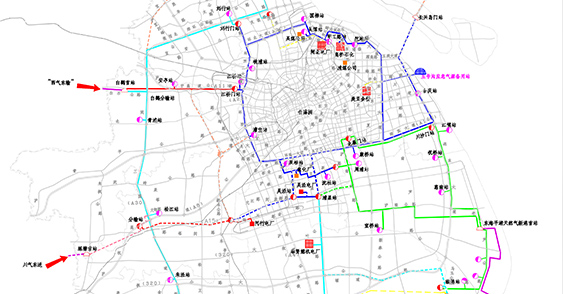

The sewage connection project between Zhuyuan and Bailong Port involves a new 19-km inter-plant pipeline with a capacity of 800,000 m3/d and two new terminal lift pump stations. The project connects the Bailong Port Sewage Treatment Plant and Zhuyuan Sewage Treatment Plant via pipeline and pump station so as to realize the complementary capacity between sewage treatment facilities in this region. The project, upon its completion, can connect two sewage treatment systems in Zhuyuan and Bailong Port. It can play multiple functions, such as cross-area emergency dispatch and water allocation, and enhance the functional resilience of sewage transmission and treatment system.

In the sewage connection project ZB1.2 (pipeline engineering) between Zhuyuan and Bailong Port, a new pipeline of 9,142 m was newly constructed. The longest jacking path is 1,057.5 m. The project penetrates 11 bridges, 2 high-pressure gas pipes, 2 overpasses in Gaodong, 1 water pipe at Qingcaosha and 1 aviation gas pipe. During the jacking process, the advanced non-constant flow simulation technology with full conservation of mass was adopted to overcome the technical difficulty in intermittent operation of gas-liquid two-phase flow. Simultaneously, the pipeline structure health monitoring system was used to conduct on-line monitoring for pipelines with large diameter and long conveyance distance so that the pipeline structure status can be perceived accurately.

Business sector: Energy (Hydrogen energy)

Location: Foshan City, Guangdong Province

Commencement time: October 2021

Participation mode: EPC design, Procurement and construction

The project is located at Gaoming District, Foshan City, Guangdong Province, and covers a total area of 6, 961.8 m2. Centering on the development theme of “energy + technology towards carbon neutrality”, the project creates an integrated station for hydrogen production from natural gas and in-station hydrogen refueling. Among them, the hydrogen production module adopts the first set of skid-mounted natural gas-hydrogen production facility in China with independent intellectual property rights. It is designed to construct a comprehensive energy supply station integrating natural gas hydrogen production, photovoltaic power generation coupled with water electrolysis hydrogen production, hydrogen refueling, gas feeding and other functions.

In December 2021, the natural gas-hydrogen production facility successfully produced highly pure hydrogen, with the highest hydrogen purity up to 99.999% worldwide. In August 2022, the Phase I of the project was officially put into operation. It has filled the gap in the domestic industry and been reported with a feature story by CCTV news channel.

Business sector: Energy

Location: Yancheng City, Jiangsu Province

Commencement time: February 2022

Participation mode: PC engineering procurement construction

Project breakthroughs: It succeeds in "three firsts".

The project mainly includes the gasoline and natural gas (LNG) refueling unit and the hydrogen refueling and natural gas (CNG) refueling unit. The project include the principal technology of a jointly constructed station as well as the civil, electrical, automatic control, water supply and drainage, fire and other relevant public supporting facilities. The station can provide refueling services for 20 new energy vehicles simultaneously, and thus form a four-in-one three-dimensional energy services for “hydrogen refueling, LNG refueling, gasoline refueling and recharging”. The project adopts the construction mode that integrates multiple stations. In addition to its intensive land usage, it is also featured by its high efficiency, green attribute and friendliness. It explores a development path of organic integration of charging station and traditional refueling and natural gas station. The project will accelerate the development in new energy vehicle industry and strive to become an energy demonstration case that can be replicated and promoted, so as to accumulate experience for similar projects in the future.

The project succeeds in "three firsts", namely the first “primary (station) with standard (station)” project for compressed natural gas station in China, the first integrated gasoline, natural gas, hydrogen and electricity energy project in Jiangsu Province, and the first mounted (overhead) refueling project in Jiangsu Province.

Business sector: Energy (Hydrogen energy)

Location: Cixi City, Zhejiang Province

Commencement time: May 2021

Participation mode: Engineering procurement construction

Project breakthroughs: The first hydrogen refueling station without fixed cylinder pack in Zhejiang Province

This project works as a supporting equipment of the supporting facilities for hydrogen supply and storage for pilot production line with an annual capacity of 1,000 sets of fuel cell bipolar plates and cell stacks of Ningbo Lvdong Fuel Cell Co., Ltd. under SPIC. The project comprises new supporting facilities for hydrogen supply and storage that provides 35-MPa high-pressure hydrogen refueling service. Its daily hydrogen refueling capacity is 500 kg and can meet the refueling demands of 20 buses with hydrogen fuel cells. The project is located at the SPIC Hydrogen Energy Industry Project Base in Cidong Binhai Economic Development Zone, Longshan Town, Cixi City. The station adopts a non-fixed cylinder pack assembly and the dual external transmission scheme of direct pipeline supply and vehicle refueling. It has the advantages of less land, low construction costs, good security, small staffing and low operation costs. The fuel cell pilot production line project serves as not only a key initiative for SPIC to respond to the national hydrogen energy strategy and to open up the hydrogen energy industry chain, but also the concrete embodiment of the "three innovations" and “industrialization, marketization and scale expansion” of the hydrogen energy strategy implemented by STEC Shanghai Energy Construction Group Co., Ltd.

Business sector: Energy (Hydrogen energy)

Location: Fengxian District of Shanghai Municipality

Commencement time: September 2021

Completion / operation time: December 2021

Participation mode: Integrative equipment procurement and construction contract

Project breakthroughs: It is the first jointly constructed oil-hydrogen station in Shanghai and the smallest jointly constructed oil-hydrogen station on the same scale in China.

This project is a key project for the joint development in hydrogen energy by Petro China and Shanghai Shenneng Group. It is a demonstration station and benchmark station for hydrogen energy utilization in Lingang New Area of Shanghai. The project is located on the north of the intersection between Pingxiao Road and Zhenglang Road in Lingang New Area, Situan Town, Fengxian District, Shanghai Municipality, covering an area of 2,900 m2. The hydrogen system of this project adopts the design of 50-MPa hydrogen storage and distribution. The hydrogen storage scale is 800 kg. It adopts a dual machine refueling mechanism. The gasoline refueling system adopts four sets of 30-m3 vacuum dual capacity pipe and four machine dual fuel and four-gun scheme. The station is also established with two fast charging parking lots. The project has the advantages of small footprint, good economic benefits, energy saving and environmental friendliness. The successful operation of this project not only improves the standardized management level of STEC Shanghai Energy Construction Group Co., Ltd. but also provides high-quality engineering design and management services for Petro China and Shanghai Sheneng.

Business sector: Energy (Natural gas)

Location: Foshan City, Guangdong Province

Commencement time: It is expected to be in September 2022.

Participation mode: Engineering procurement design and construction

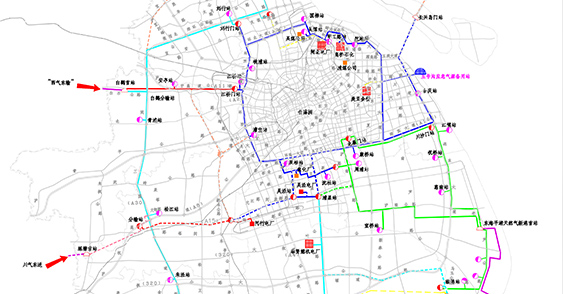

Located in Foshan City, Guangdong Province, the project comprises a pipeline as long as about 23 km, the expansion of Xiqiao pressure-regulating station, and the construction of Jinben pressure-regulating station. The total investment of this bid section is about CNY 525.16 million yuan. The project will be connected with the existing high-pressure pipe network system in Foshan, so as to construct a north-south gas transmission channel and to connect the downstream urban medium-pressure transmission and distribution system. The project will meet the gas demand from various urban gas users in this region, strengthen the stability and security of gas supply, and facilitate the development in low-carbon energy.

Business sector: Energy (Hydrogen energy)

Location: Qingdao City

Completion / operation time: April 2022

Production time: May 2022

Participation mode: Design

Project breakthroughs: The first hydrogen refueling station at a port in China.

The designed daily hydrogen refueling capacity of the project is 1000 kg. The project has been constructed in two phases. Phase I hydrogen refueling station saw a total investment of CNY 12 million yuan and covered an area of about 4,000 m2, which includes compressor, hydrogen storage cylinder, hydrogen refueling machine, water chiller and other devices. This project has acquired the first Hydrogen Cylinder Refilling License among hydrogen refueling stations in Qingdao City, and been the first completed hydrogen refueling station at a port in China at present. The project has gone through all the completion acceptance and qualification procedures for planning and fire control, and been operated under full qualification and license. This station, upon its operation, has successfully met the demand from vehicles for hydrogen refueling in Qianwan Port Area of Qingdao Port in Shandong Province. It plays an demonstrative and leading role in the construction of "hydrogen port in China".

Business sector: Energy (Natural gas)

Location: Shenzhen City, Guangdong Province

Commencement time: August 2022

Participation mode: Engineering procurement design and construction

Located in Longgang District of Shenzhen City, the project covers 8 sub-districts, 44 sub-projects, 114,000 households and a total investment of about CNY 795.552 million yuan. The project, upon its completion, has laid a solid foundation for Longgang District to achieve the goal of eliminating gas cylinders by the end of 2023.

Business sector: Gas energy - energy transmission

Location: Yangpu Economic Development Zone of Danzhou City, Hainan Province

Commencement time: September 2021

Participation mode: Engineering procurement construction

The phase II project of supporting utility tunnel for ethylene project in Hainan Yangpu Petrochemical Functional Zone is located in the road network area for ethylene project to the northwest of Yangpu Port. The project was designed to cover the utility tunnel works on the Yuanyi Road, Yuaner Road, Yuansi Road and Pusi Road. The utility tunnel is as long as about 7.2 km and as wide as about 6 to 9 m. It covers a total area of about 75,400 ㎡. It adopts a form of four-story steel structure truss. The project is divided into four parts. The first part extends from the intersection between Binhai Road and Yuanyi Road to the intersection of Pusi Road along the direction of Yuanyi Road; the second part extends from the intersection between Binhai Road and Yuaner Road to the Carbon 5 carbon 9 project along Yuaner Road; the third part extends from the intersection between Pusi Road and Yuansi Road to the thermal power plant along Yuansi Road; The fourth part extends from the intersection between Pusi Road and Yuanyi Road to the intersection of Yuansi Road. The project includes the utility tunnel engineering and its public grounding, the public weak current work, the video surveillance, the anti-collision facilities, and other ancillary facilities for utility tunnel.

Business sector: Construction and real estate

Location: Mianyang City, Sichuan Province

Commencement time: May 25th, 2022

Participation mode: EPC design and construction

The Project of supporting facilities for infrastructure and Zone C of New Display Industrial Park in Mianyang City serves as one of the special parks in the Three-year Action Plan for Cultivation and Development of 5+1 Key Special Parks in Sichuan Province. It works as the driving force for the development of economy and society in Mianyang High-tech Zone.

The project is located in Shiqiaopu and on the east of the High-tech Zone and the south of the Anchang River. Its traffic location is superior, with 6 km away from either the main city or Nanjiao airport, and 3 km away from Mianyang Station. The total planning area of the project is 352,937.106 m2 and the total construction area is 453,945.23 m2. This project comprises 22 buildings and its construction content mainly includes the new standard plant, the production and R&D office buildings, the research and training building, the supporting rooms, the outdoor landscape, the road and relevant supporting facilities.

Business sector: Construction and real estate

Location: Yueyang City

Commencement time: October 2021

Participation mode: EPC design and construction

Project breakthroughs: The jump warehouse construction method was first adopted in Yueyang area.

Located in Huashan District, Yueyang City, the project of outpatient, emergency rescue and medical technology complex of Yueyang Central Hospital was constructed with a total area of 213,151.33 m2, 2 floors underground, 5 floors above ground, and a total building height of 23.95 m. The structural form adopts the framework structure; the foundation is made of lower column pier and raft foundation; the raft is as thick as 600 mm. The basement structure is 329 m long from east to west and 298 m wide from north to south. The structure was divided into 25 casting blocks by a retractable post-casting belt with a length of 6,000 m. The project department reduces the post-pouring belt by over 2,000 m through jump warehouse method. They have overcome many difficulties, such as the construction with ultra-long structure, the difficult seepage prevention due to the deep and large foundation pit, the difficult construction organization and control due to small construction site, and the tight schedule.

The project of the central hospital has promoted the development in medical and health undertakings in Yueyang City. It has deepened the reform in the medical and health system, optimized the allocation of medical and health resources, and improved the resource utilization efficiency. It meets the demands at different levels from the masses for medical and health services, and protects peoples health in an all-round and full-cycle manner.

Business sector: Rail transit

Location: Shanghai Municipality

Commencement time: May 2022

Participation mode: PPP mode

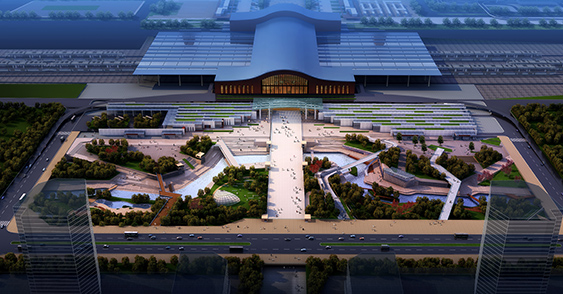

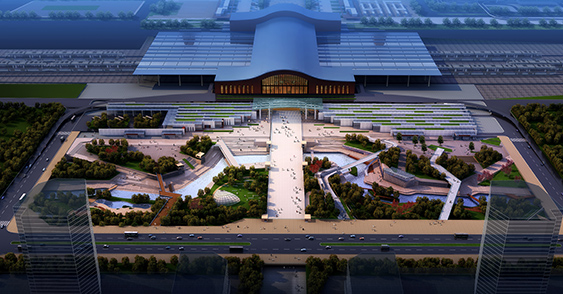

The PPP project for integrated traffic hub of Wenling Station is located at the Railway New District of Wenling City, Zhejiang Province, with a total construction area of 108,800 m2. The project mainly includes four sub-projects: The east square hub, the supporting housing for rail transit, the bus transfer center and the parking building.

Facing the challenges like the wide work plane, the large volume of steel structure and the great number of buildings / structures, STEC made early plans and careful preparation. It escorted the construction of steel structure through early survey, GPS positioning, BIM simulation, advance deepening and refining of steel structure process. During the construction of deep foundation pit, STEC actively dealt with complex geological conditions, difficult support, super typhoon and other adverse factors. Thus, it ensured that the land subsidence, the maximum settlement of ramp pier and station pier column were in their controllable ranges, and guaranteed the safe operation of railway. STEC has made joint and practical efforts to construct a new traffic pattern and secured the largest and most beautiful city entrance for Wenling.

Business sector: Tunnel / rail transit

Location: Jiaxing City, Zhejiang Province

Commencement time: May 2020

Completion / operation time: June, 2016 for the first section and June, 2022 for the whole line.

Project breakthroughs: The first tram in Zhejiang Province.

As the first tram in Zhejiang Province, the Jiaxing Tram Project is one of the "one hundred key projects in one hundred years" and one of the ten landmark projects of Jiaxing City. It is also a major transportation facility project for Jiaxing to implement the national strategy of Yangtze River Delta integration and construct a central hub city in the core area of the Yangtze River Delta.

The Phase I project passes through 49 intersections along the way, including 27 signalized intersections and 22 non-signalized intersections. The average interval between intersections along the route is relatively close, basically 318 m to be specific. Phase I passes through 16 large and small bridges and under nearly 1 km of railways, and sees complex construction environment. The large engineering volume involves many different professional contents, such as sub-grade, bridge, track, road, drainage, greening, underground structure, housing construction, power supply, communication, operation and dispatching, geomantic electricity and escalator, intelligent building, intelligent transportation, ticket sales system, process equipment, etc.

It only took 370 days for STEC to open the first section of Jiaxing Tram. This speed has broken the conventional domestic tram construction schedule, and set a new benchmark for similar tram construction projects.

Business sector: Rail transit

Location: Nanjing City

Commencement time: December 2016

Participation mode:Engineering procurement construction

Shield tunneling machine specifications: Earth pressure balance shielding machines with diameters of 6390 mm, 6440 mm, 6450 mm, etc.

Nanjing Metro Line 5 serves as a key line from southeast to northwest in Nanjing rail transit network and is positioned as an urban trunk line. The line covers a total length of 37.4 km and has 30 underground stations. Among them, 14 are transfer stations. The line is the "king of transfer stations". There are a total of 10 bidding sections for the whole line, of which 6 are contracted by STEC. They mainly comprise 21 stations, 22 shield sections and other ancillary structures.

Nanjing Metro Line 5 has been constructed under multiple difficulties. First, the stratum conditions are complex and changeable, with intersecting floodplain, sentry and other landforms. Sand layer, pebble layer and clay layer often interact with each other; non-layered structure is obvious, and formation pinching is everywhere. Second, there are dense surrounding buildings along the line, of which most are protective buildings, cultural relics, greening zones. They set high requirements on protection measures. Third, the shield tunneling machine passes under the two operating subway lines, penetrates through important buildings, structures, roads, bridges, rivers and other complex and high-risk areas, setting high requirements on protection measures and standards.

Business sector: Subway

Location: Fuzhou City, Fujian Province

Commencement time: March 2018

Participation mode:Ordinary engineering procurement construction

Shield tunneling machine specifications: Earth pressure balance shielding machine

The first bid section of Phase I Project of Fuzhou Metro Line 4 is about 9.57 kilometers in length and located in Cangshan and Gulou Districts of Fuzhou City. It contains 8 stations, 9 intervals, 1 exit and entry line, and Hongtang depot. All of the 8 stations in this section are underground island stations, among which Jinniushan Station and Dongjiekou Station are three-storey underground stations, and the rest are two-storey underground stations. The interval tunnel has an outer diameter of 6.2 m and an internal diameter of 5.5 m. North Baima Road Station, Dongjiekou Station and Provincial Hospital Station are all constructed through full-cover reverse digging method. Fuzhou Metro Line 4 forms a part of the northeast half of the combined main urban ring of Fuzhou. The project is of great significance for Fuzhou to open the urban architecture, support the urban development, and facilitate the development in the Convention and Exhibition Center and Yixu areas.

Business sector: Railway

Location: Shanghai

Commencement time: December 2021

Participation mode:Engineering procurement construction

Shield tunneling machine specifications: Slurry-gas balance shield tunneling machine with a diameter of 10 m

Project breakthroughs: The first shield-type railway tunnel for both passenger and freight dug in a soft soil area in China; the first railway tunnel crossing the Yangtze River and Huangpu River in China; the first fully enclosed and lined shield tunnel in China.

Shanghai-Nantong Railway Phase II (Section from Taicang to Situan) starts from Taicang Station in the north and ends at Situan Station in the south. It passes through Taicang City under Suzhou City, Jiangsu Province, and Jiading District, Baoshan District, Pudong New Area and Fengxian District in Shanghai. The line has a total length of 111.8 km.

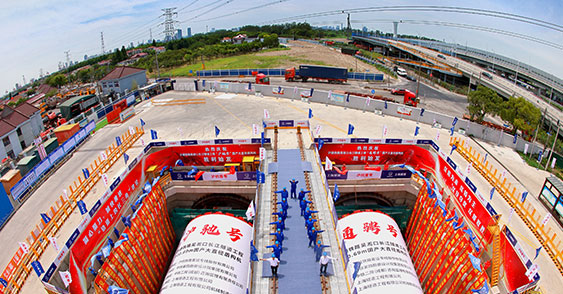

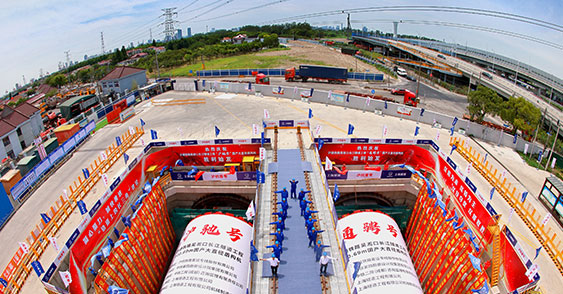

Among them, Wusongkou Yangtze River Tunnel (Bids HTZQⅡ-4 and HTZQⅡ-1) is the control project for Shanghai-Nantong Railway Phase II. The total mileage of the main line of the project is DK140+700 ~ DK151+485, with a total length of 10.785 km, of which the shield tunnel section is as long as 9.047 km (The section cross the Huangpu River and the Yangtze River is 4.7 km, and the land section is 4.347 km).

STEC adopts the independently developed shield tunneling machine with a large diameter of 10.690 m. It will be tested by the curve starting line, the shallow soil covering and the continuous crossing of Jiangdong Road and G1503 Belt Expressway. Next, it will directly face a series of extreme challenges posed by many buildings and structures: Penetrate under the Pudong tunnel section along the river, Binjiang Forest Park, Huangpu River Levee and Wusong Jetty; cross the international cruise terminal and the public security wharf; penetrate through the small sand back box culver, the Yangtze River Embankment and the pump station of the 14th district of Shanghai Port; penetrate under the wind channel of tunnel along the river, the Puxi open section, the overpass of tunnel along the river, the elevated Line 3 and the viaduct on Tongji Road. The minimum turning radius of shield tunneling machine is 778 m. During the long-distance excavation construction, the top priority is to maintain the micro-disturbance to surroundings.

On June 27th, 2022, the launching ceremony for "Huchi" and "Tongcheng" shield tunneling machines on the Shanghai-Nantong Railway marked that Wusongkou Yangtze River Tunnel Project for Shanghai-Nantong Railway Phase II officially entered a new chapter for shield tunneling construction.

Business sector: Underground space

Location: Ningbo City, Zhejiang Province

Commencement time: April 2022

Participation mode:Engineering procurement construction

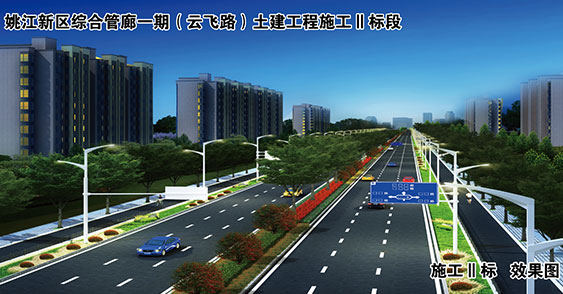

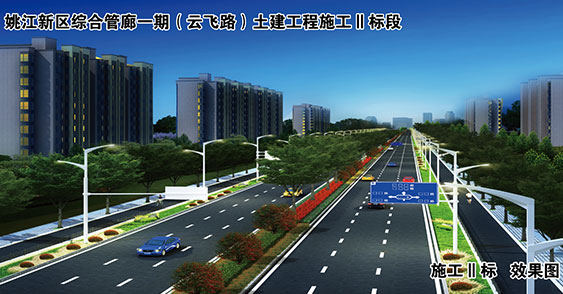

Section II (Shaodu Road - Guangyuan Avenue section) of Yunfei Road Phase II (Shaodu Road - Middle Hongtang Road) project covers a total length of 1670.56 m. The main construction comprises road engineering, operation maintenance engineering, drainage engineering, bridge engineering, etc. The section II of civil engineering construction of Yaojiang New Area Utility Tunnel Phase I (Yunfei Road) is a trunk-type comprehensive utility tunnel established under the sidewalk, the non-motor lane and the separation belt (biological retention zone) on the north side of Yunfei Road.

This project belongs to the joint construction of road and utility tunnel, which has the following difficulties. First, the excavation depth of utility tunnel foundation pit should be 5 to 10 m; the tunnel crosses 3 rivers in total so the foundation pit must be excavated with safety. Second, the waterproof grade for tunnel in this project is grade two so the main body of the project has a high waterproof requirement.

After completion, the project will drive the development in Yaojiang New Area and promote the new urbanization and the modernized urban construction in Yaojiang New Area. It will improve the comprehensive carrying capacity of urban infrastructure and facilitate the comprehensive utilization of underground space resources.

Business sector: Underground space

Location: Shanghai Municipality

Commencement time: June 2021

Participation mode: TOD mode

Project breakthrough: The first underground parking lot for municipal railway in China

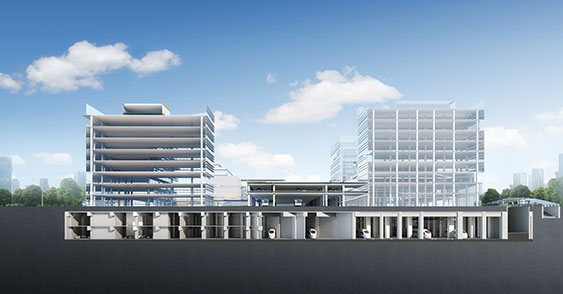

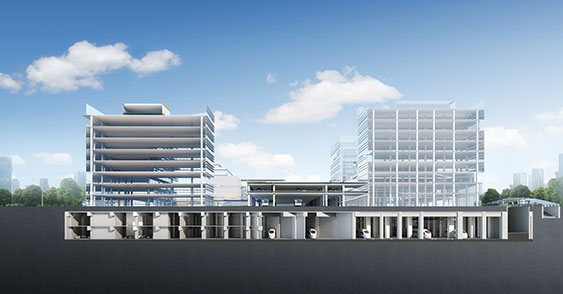

Shenkun Road parking lot and comprehensive upper cover development project is an integrated TOD development project containing municipal railway, urban rail transit, medium volume bus, business community development and other functions. It is not only an important hub project for the comprehensive transportation development in Shanghai during the “14th Five-Year Plan” period and the "Five New Cities" comprehensive transportation system framework, but also another crucial connectivity project for the Yangtze River Delta integration and Hongqiao International Open Hub strategies.

The project is located in the core area of Shenkun Road, the "South Gate" of Shanghai Hongqiao International Open Hub, with a total construction area of over 500,000 m2. It is close to Hongqiao traffic hub in the north, adjacent to the completed Huaxiang green land in the west, and located at the intersection node between airport contact line and Jiamin Line. It serves as a crucial node for the near Shanghai area to access the municipal railway network in the future.

STEC possesses a lot of construction and management experience in the simultaneous construction and transformation of rail transit engineering and building complex, the supporting municipal engineering, the advantages of the whole industry chain, and the experience in industry resource integration. It continues to deepen the TOD project construction and management system during the construction period so as to provide reference for the construction of Shanghai rail transit complex.

Business sector: Underground space

Location: Nanjing City, Jiangsu Province

Internal trial operation time: in 2022

Participation mode: Construction

Project breakthrough: The first intelligent caisson-type parking lot constructed by VSM sinking vertical shaft tunneling technology in China.

In this project, the world-leading VSM sinking shaft tunneling technology is adopted to "dig" a three-dimensional space for 200 small vehicles in a narrow area of 390 m2. On average, it takes only 1.95 m2 of ground space to park one vehicle. Citizens can gain access to their vehicles via the landscape entrance and exit on the ground. It takes them as little as 90 s to receive a high-quality parking experience. This project provides experience and reference for the intensive use of urban land resources, the development and utilization of underground space, and the expansion of effective supply of parking facilities.

The UP intelligent parking scheme proposed by STEC conforms to the development trends, such as "smart city" and “Internet +”, and fully draws on the experience and exploration on domestic and foreign solutions for parking difficulties. Public hot spots, such as downtown areas, see large flow of people and vehicles, dense layout of old buildings and tight surrounding land resources. In view of those urban difficulties, STEC creates the "three new" intelligent parking system that integrates new technology, new platform and new mode so as to solve the parking difficulty and fully activate the service efficiency of UP underground garage.

Business sector: Roads and bridges

Location: Lankao County of Kaifeng City and Fengqiu County of Xinxiang City in Henan Province

Commencement time: The main project is scheduled to commence on November 1st, 2022, (Subject to the actual commencement instruction), and the temporary steel trestle started on June 10th, 2022.

Participation mode: BOT mode

Project breakthrough: The subbridge superstructure of the Yellow River Bridge in this project adopts the whole hole erection of 100-m span steel concrete composite beam. This technology is another innovative breakthrough after the whole hole erection process of 80-m span steel beam of Mengzhou Yellow River Bridge in China. It will form a new achievement in bridge equipment research and development and installation technology.

The Lankao County of Kaifeng City and Fengqiu County of Xinxiang City in Henan Province starts from Lankao County, crosses the Yellow River to the west, and ends in Fengqiu County, with a total length of 30.263 km. The main line of the project adopts the expressway standards with six lanes in two directions, a subgrade width of 34.5 m, a design speed of 120 km/h. The Yellow River Bridge is as long as 9.104 km.

The maximum height of the main tower of the Yellow River Bridge is 160.5 m, with high spatial positioning accuracy and difficult line-type control. The foundation pile adopts the pile foundation with super depth and super large diameter (as deep as 106 m). The generous amount of concrete construction underwater tests STECs delicacy management. The subbridge superstructure of the Yellow River Bridge in this project adopts the whole hole erection of 100-m span steel concrete composite beam. This technology is another innovative breakthrough after the whole hole erection process of 80-m span steel beam of Mengzhou Yellow River Bridge in China. It will form a new achievement in bridge equipment research and development and installation technology.

The project serves as a key construction project of “13445” expressway engineering in Henan Province. Upon its completion, the project is of great significance for China to facilitate the strategy of the rise of central China, accelerate the development in "Central Henan Urban Agglomeration", promote the Zhengzhou metropolitan area, and advance the high-quality development in the Yellow River Basin.

Business sector: Roads and bridges

Location: Anyang City of Henan Province

Commencement time: October 2021

Participation mode: BOT mode

Anyang-Luoshan Expressway is one of the 16 north-south vertical channels in the Henan Province Expressway Network Planning (2021-2035), connecting 9 cities and 16 counties in Henan Province. Upon its completion, the project will form a new vertical channel between the Beijing-Hong Kong-Macao Expressway and the Daqing-Guangzhou Expressway. It will connect the Beijing-Tianjin-Hebei urban agglomeration and Xiongan New Area in the north and the urban agglomeration in the middle reaches of the Yangtze River in the south. The project is of great significance for China to further strengthen inter-regional economic integration and relieve the traffic pressure on the Beijing-Hong Kong-Macao Expressway.

Covering a total length of 38.9 km, Bid SG-4 of the Yuan-Hebei provincial boundary to Yuanyang section (Lankao-Yuanyang Expressway) of the Anyang-Luoshan Expressway involves 1 hub, 3 interconnections, 1 service zone, 51 channels, 33 box culverts and 54 bridges. The standard design of the project is six lanes in two directions; the design speed is 120 km/h and the pavement width is 34.5 m. Builders have vigorously promoted the implementation and application of emerging technologies of smart construction site in Anyang-Luoshan Expressway project. The intelligent control has efficiently facilitated project construction. STEC introduces intelligent prefabricated box girder workshop and uses the independently developed bridge prefabricated component production information management platform so as to ensure that component production information can be tracked throughout the process and the quality can be controlled. Pavement construction information system assists the construction and thus realizes intelligent identification of pavement construction status and quality. In this way, the system promotes the integration mode of factory production, information management and intelligent control.

Business sector: Roads and bridges

Location: Shaoxing City, Zhejiang Province

Commencement time: September 2021

Participation mode: PPP mode

The PPP project of connection line between Hangzhou-Jinhua-Quzhou Expressway to Hangzhou-Shaoxing-Taizhou Expressway is jointly undertaken by Zhejiang Communications Investment Co., Ltd., Zhejiang Communications Engineering Co., Ltd., STEC Shanghai Infrastructure Co., LTD., and Shanghai Road and Bridge Co., Ltd. The project starts from the north side of Zhangjiafan Hub of Hangzhou-Jinhua-Quzhou Expressway and ends at Fuquan Hub of Hangzhou-Shaoxing-Taizhou Expressway. The route is as long as 22.028 km. The main construction tasks involve subgrade, bridge, culvert, tunnel, pavement, traffic safety, afforestation, etc.

The connection line of Hangzhou-Jinhua-Quzhou Expressway forms an important part of expressway network in Zhejiang Province. It is not only the main fast channel connecting Hangzhou and Shaoxing but also a key channel for Shaoxing City to integrate into Hangzhou metropolitan area and to realize the integration of three districts. Simultaneously, it is also an important link of the outer ring expressway of Keqiao District, Shaoxing City.

STEC scientifically plans and carefully organizes the construction, solves the construction and technology difficulties, addresses the bad geological section, and then get through the construction bottleneck. Based on good construction organization, STEC reasonably allocates resources and keeps balance in construction. It takes environmental protection seriously, carries out green, environmental and high standard construction, and penetrates through forest land, reservoirs and streams. STEC is committed to construct a “safe, ecological and environmentally friendly” highways and contributes to the integrated and high-quality development in the Yangtze River Delta.

Business sector: Roads and bridges

Location: Anyang City of Henan Province

Commencement time: December 2021

Participation mode: BOT mode

The Bid AHTJ-3 of Anyang-Hebi section of Anyang-Xinxiang Expressway will effectively relieve the traffic pressure of the Beijing-Hong Kong-Macao Expressway and optimize the operation efficiency of the road network. It will enhance the Henan-Hebei transportation corridor, improve the layout of regional road network, and strengthen the connection between North Henan and Zhengzhou metropolitan road network.

The Bid AHTJ-3 of Anyang-Hebi section of Anyang-Xinxiang Expressway is as long as 18.84 km. The bid involves 16 bridges, 3 middle bridges, 3 overpasses, 29 culverts, and 2 medium and long tunnels, with the bridge-tunnel ratio over 40%. This project, an important section of the highway network planning in Henan Province (2021-2025), will further improve the “米+井+人” shaped integrated transportation corridor in Henan Province upon its completion. It plays a significant role in solving the expressway connection between Anyang and Hebi and promoting the regional economic development.

Business sector: New materials

Production place: STEC Shanghai Urban Construction Materials Co., Ltd.

Production time: in 2009

Representative application projects: Poly Theater, Beiheng Passageway and Warm Pavilion

Application scenario: Low-carbon building decoration

Fair-faced concrete serves as a kind of artistic expression technique for modernism in architecture. The fair-faced concrete adopts the natural color of cast-in-place concrete as finish. Its simple, natural and stable appearance delivers an generous and inclusive atmosphere and an eclectic unique artistic beauty. Simultaneously, it needs a cast-in-place molding and achieves the unified difference in color, the smooth surface, the homogeneous bubble and the clear texture. After casting, there is no need for any painting, tile, stone and other processes. In this way, the material shows the plain color decoration effect of concretes "returning to simplicity". This material also embodies the concept of environmental protection because it reduces the surface decoration materials, saves the chemical products, such as coating and finish, and lowers a large amount of construction dust and waste.

Business sector: New materials

Production place: STEC Shanghai Urban Construction Materials Co., Ltd.

Production time: 2021

Representative application projects: The anti-floating project on South Square of Shanghai Hongqiao Hub Project, the anti-floating foundation project of Shanghai World Expo VIP Natatorium, the counterweight block for the first Sheshan astronomical telescope in Asia, etc.

Application scenario: Foundation in soft soil with high water content

The anti-floating counterweight concrete with low-carbon steel slag researched and developed by STEC Shanghai Urban Construction Materials Co., Ltd. is kind of heavy concrete with high specific gravity. It takes the high-quality steel slag as raw material and goes through composite preparation. It is 1.5 times heavier than ordinary concrete and therefore can effectively solve the problems of structural anti-floating counterweight and building balance counterweight due to the lack of structural deadweight in soft soil foundation engineering.

Business sector: New materials

Production place: STEC Shanghai Urban Construction Materials Co., Ltd.

Production time: 2016

Representative application projects: The comprehensive utilization reconstruction project of Expo Axis and the underground filling project of central enterprise headquarters

Application scenario: It applies to the roofing or wall insulation, the utility pipelines, the bridges, the foundation pits and other engineering filling parts.

Foamed concrete is named as "one of the most functional bulk inorganic lightweight materials so far". It is a new kind of porous lightweight concrete material formed by physical foaming method. It lightens the previously heavy concrete and endows concrete with dozens of functions, such as heat preservation, thermal insulation, sound absorption, fire resistance, waterproof, shock wave resistance, electromagnetic wave resistance, air permeability and corrosion resistance. Due to its lightweight, foam concrete can reasonably reduce the load and compensate the free settlement difference after its utilization for backfilling in construction and geotechnical engineering. After its utilization in wall surfaces, foam concrete can not only keep ambient environment warm in winter and cool in summer, but also solve the problems of falling off, fire prevention and durability in traditional external wall insulation materials once and for all.

Location: Shaoxing, Zhejiang

Project period: 2021-2022

It is an intelligent operation and maintenance management platform for transportation network infrastructure for transportation supervision, operation and maintenance departments. It mainly serves the construction, operation and management of "six horizontal and eight vertical" expressway network in Shaoxing, providing facilities and equipment asset management, maintenance and repair business management, maintenance decision management, and development and maintenance of operation and maintenance APP by a series of intelligent infrastructure operation and maintenance integrated service solutions such as compilation of digital operation and maintenance guidelines, deployment of intelligent operation management platform, and intelligent analysis of operation and maintenance big data. The platform has standardized and normalized the operation and maintenance of infrastructure, continuously precipitated effective data from unified standard data and extracted reproducible and generalizable data models. It has effectively assisted operation and maintenance personnel in special research and analysis, realized data-assisted decision-making based on facility safety and operation and maintenance safety supervision by connecting 440 Internet of Things sensors, and improved the emergency command ability and road management efficiency.

Location: Jiaxing, Zhejiang

Project period: 2020-2021

It is the first component-level water facility and equipment management platform based on BIM+GIS technology, which mainly includes functional modules such as monitoring network, pipeline operation and maintenance, data analysis, hydraulic model, daily dispatching, BIM+GIS, water balance, facility and equipment management and emergency command. It can effectively identify and predict the bottleneck of urban drainage system and its possible problems and risks, and provide professional analysis and management of water pipelines, water quality, leakage, etc. Almighty hard core of refined management: The digital city twin base formed by BIM is adopted to form a visual and component-level digital asset operation and management mechanism, which provides a digital and information foundation for the integration of planning, construction and management in the field of sewage engineering in Jiaxing. Combination of virtual and real daily maintenance: Based on MR mixed reality management platform, inspection personnel can inspect through mobile terminal inspection APP, realizing the combination of "virtuality" and "reality" between BIM model of underground pipelines and inspection and maintenance site.

Location: Shanghai

Project period: From 2021 to now

Shanghai rail transit airport link line is 68.6km in length. The construction management quality and efficiency of the airport link line project can be ensured in an all-round way by the construction management platform + smart site platform. Based on the company's own BIM consulting + engineering construction information + system integration solution, the construction management platform of the project is to integrate the digital twin concept into the site safety, quality and schedule management to realize the digitalization of engineering management and the visualization of construction technology. The smart site platform is based on IOT technology to realize fine management of personnel and environment and minimize blind spots in safety management. During the implementation of the project, the company, guided by operation and maintenance, has introduced GIS+BIM engine with independent intellectual property rights, combined with UAV tilting photography, virtual reality, Internet of Things and other information technologies, comprehensively implemented BIM application technology in Shanghai railway, thereby building the municipal railway standardized industrial system, and getting through the whole life cycle data stream of "planning-design-construction-operation" of the project.

Location: Foshan, Guangdong

Project period: 2019

Intelligent transportation control platform of Foshan 1st Ring Expressway is a traffic signal control platform developed for local traffic signal timing optimization centers based on the regional coordination control theory. By optimizing traffic control and intelligent operation and maintenance management, it is to improve traffic efficiency, ensure traffic safety and establish a service guarantee system for citizens' travel and urban traffic management. The platform mainly forms optimization schemes for single point, main line and regional traffic signal control through the analysis and calculation of the urban traffic network on the whole time, whole area and whole amount, and makes real-time evaluation and feedback on the optimization effect of the schemes, forming optimization suggestions for traffic control to ensure the optimal effect of regional traffic control. In addition, with intelligent operation and maintenance management and other functions, it can provide real combat business linkage for traffic management business scenarios, such as real-time supervision of key vehicles, optimization of traffic operation management, intelligent management and control of events and alarms, monitoring and analysis of equipment faults and abnormalities.

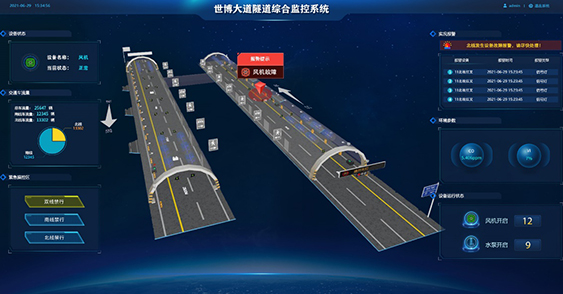

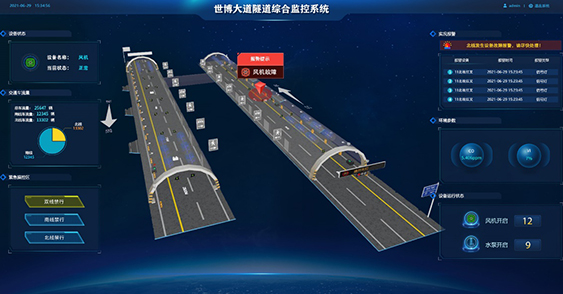

Location: Shanghai

Project period: 2020-2021

Integrated tunnel monitoring system of Shibo Avenue is an integrated intelligent management and maintenance platform developed for the needs of intelligent management and maintenance of road facilities. According to the facility group/facility operation management characteristics and requirements, the platform can customize the whole set of operation management scheme. In the multi-dimensional integrated management mode of "management, operation and maintenance, monitoring, control, command and dispatch", service functions such as road condition monitoring, traffic operation management, mechanical and electrical operation control optimization, emergency management coordination, operation and maintenance management and public information services are integrated, and integrated tunnel monitoring solutions around the closed-loop of "sensing, warning, decision, control and analysis" business are provided. (1) Guided by the management of facility fixed assets, the platform monitors, controls and manages the operation and fault treatment of various types of equipment in the tunnel, processes various state data and operation data in the tunnel, and realizes health diagnosis, pre-maintenance and other functions through the efficient collection of IOT data, data aggregation and environmental condition perception. (2) Guided by the comprehensive tunnel management and control, it improves the comprehensive ability of equipment control, event warning and process management, realizes the operation simulation and emulation of the system, provides operation suggestions and optimization schemes, takes charge of rescue command and provides emergency plans in emergency situations such as accidents and fires.

Location: Shanghai

Project period: From 2022 to now

It is an intelligent transportation control platform by unified planning, management and operation in the field of mass transportation for transportation coordination management needs of joint logistic support and joint action. By the analysis and calculation of the urban traffic network on the whole time, whole area and whole amount, it provides integrated transportation management services to improve traffic efficiency, ensure traffic safety and establish a service guarantee system for citizens' travel and urban traffic management

(1) With comprehensive, scientific and reasonable traffic information perception system, it has standardized the requirements and standards for the construction of traffic facilities and equipment, guided the reconstruction of existing roads and intersections, standardized and intelligent construction of new roads and intersections, improved the comfort, convenience and safety of residents, and provided real-time and accurate data for the traffic signal timing optimization center and traffic control platform.

(2) Through automatic collection and active discovery, it has coordinated and optimized the spatial and temporal resources of urban traffic, achieved scientific and precise management and control, and assisted in the calculation of road network traffic operation indicators and the prediction of traffic operation conditions in holidays.

(3) It has integrated traffic management data of public security departments by the data aggregation center, helping multi-department business collaboration in the traffic field, and providing services such as real-time supervision of key vehicles, optimization of traffic operation management, intelligent management and control of events and alarms, monitoring and analysis of equipment faults and abnormalities.

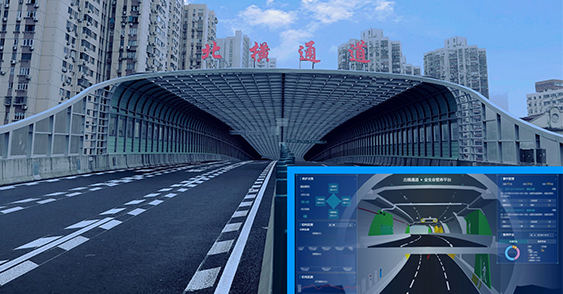

Business sector: Operation service

Location: Shanghai

Operation duration: June, 2016 till now

The North Cross Channel forms an important part of the “three-horizontal and three-longitudinal” backbone road network in Shanghai. STEC Urban Operation has formulated a professional operation and maintenance plan in view of the characteristics of “long distance (with a whole length of 10.8 km), narrow lane (3 m in width) and low space (with a height limit of 3 m)” of the North Cross Channel. The company has built and applied an intelligent management platform for the full life cycle, and configured a series of smart systems such as intelligent fire detection, civil work structure detection and ultra-high warning. It has also employed the intelligent inspection by trackless robot, the new energy equipment, the easy-cleaning paint, etc., to promote the upgrade in the whole-life-cycle mode. At the same time, the company has established an operation guarantee mechanism with “1 center, 2 emergency rescue points and 5 management zones” to give full play to the advantages of regional road network linkage. With reliance on the intelligent platform control, the company has realized central command, unified dispatch, zone-based management and rapid response, and been dedicated to forging a safe, intelligent and green “North Cross Channel” operation mode.

Business sector: Operation service

Location: Hangzhou, Zhejiang

Operation duration: October 18th, 2018 till now